Discussing the Future of Industry | Haosen Made Its Debut on FAIR plus 2025

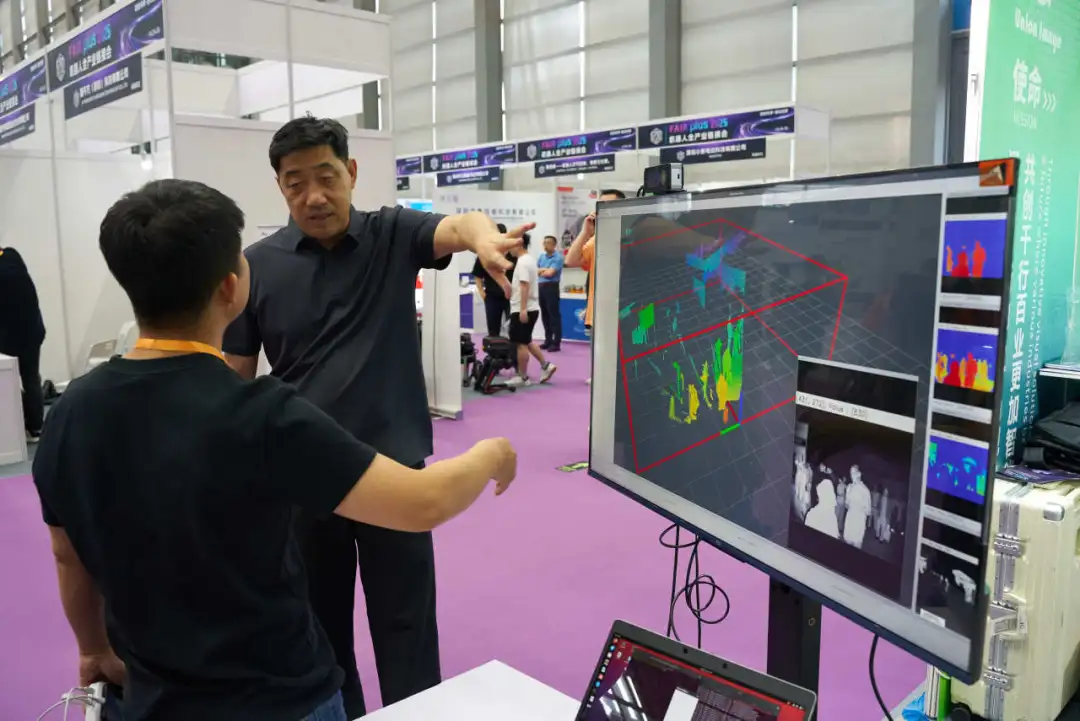

On April 24, 2025, the “Fair of AI and Robotics, plus (FAIR plus 2025)”, guided by the Industrial and Information Technology Bureau of Shenzhen Municipality and the Shenzhen Institute of Advanced Technology of Chinese Academy of Sciences, hosted by the Shenzhen Robotics Association, kicked off at Shenzhen Convention & Exhibition Center. Zhang Jizhou, Vice President of Haosen, and Dr. Li Jiong, Dean of the Haosen Intelligent Research Institute, attended as special guests. They gathered with academic experts, as well as representatives from institutions and enterprises at home and abroad to exchange insights on embodied intelligence technology advancement, product solution development, and application scenarios construction, jointly driving the commercialization of embodied intelligent robots.

This event is one of the largest and most diverse exhibitions of scientific and technological achievements in Shenzhen’s robotics industry field, as well as one of the Shenzhen’s 2025 “Win-win Results Hand in Hand” series of 100 industrial matchmaking events. Under the theme “Intelligence Igniting the Future, Chain Driving the Globe,” the event consists of theme forum, closed-door panel discussion, and parallel forum. During the forum, the 2024 Shenzhen Robotics Industry Development White Paper was officially released.

At one session of the main forum, scenario collaborative development and docking conference, chaired by Dong Kai, Director of the Science and Technology Department of CCID Research Institute under the Ministry of Industry and Information Technology (short as MIIT) and Deputy Director of the MIIT Key Laboratory for Robot Quality Foundational Generic Technology eva1uation, Dr. Li Jiong, Dean of Haosen Intelligence Research Institute, participated as a panelist, engaging in an in-depth discussion with industry elites on platform positioning and enterprise strategies in the era of embodied intelligent robots.

Deputy Director Dong Kai posed a question to Dean Li that resonated with many attendees: “Haosen is a renowned intelligent production line solution provider in the automotive and auto parts sector. Over the past year, many automakers, auto parts suppliers, and system integrators have begun entering the field of intelligent robots. Some people argue that this reflects a shift in direction due to involution competition becoming too intense. However, I believe it represents a significant opportunity for the robotics industry. Enterprises like Haosen bring deep expertise in critical processes, planning and design of complete production line systems, as well as specialized equipment development and integration, all of these capabilities provide greatly enhance for the R&D and application of intelligent robots in related fields and potentially accelerate the industrialization of various types of intelligent robots. Dean Li, how does Haosen view this trend? Could you also share insights into the collaborations between Haosen and Zhejiang Humanoid Robot Innovation Center, AgiBot, and other partners, along with subsequent plans?”

Dr. Li Jiong responded: “ Thank you all for your attention to Haosen. Indeed, many experts, customers, and peers have raised similar questions to us. As a global provider of integrated solutions for automotive powertrain and new energy three-electric (battery, motor, electronic control unit) assembly lines, Haosen has established close partnership with leading global automakers including Mercedes-Benz, BMW, General Motors, and Volvo over the past 2 decades, and accumulated vast amounts of process data resources. Our company boasts rich industrial manufacturing scenarios and in-depth knowledge of mass production processes and standards in the automotive industry. This enables us to provide abundant data and business pre-training for artificial intelligence, facilitating algorithm iteration and scenario generalization and supporting artificial intelligence’s rapid implementation in industrial environments.

Currently, material technology, manufacturing & processing, and new generation information technologies are developing rapidly. The traditional manufacturing model of fixed automated production lines for the core components of vehicles has become increasingly difficult to adapt to the demands of rapid automotive innovation driven by new technologies. This requires production lines to be more flexible and intelligent. In the past, a production line didn’t need significant changes for 5 to 10 years. However, nowadays, when we have completed the planning and design of a production line and are ready to put it into production, customers may put forward new process requirements. And even an entire production line may need to be completely rebuilt in less than three years, resulting in a low return on investment (ROI) for the vehicle manufacturers.

The rapid development in artificial intelligence technology has brought significant opportunities for Haosen. The advantages of artificial intelligence, such as self-perception, self-planning, self-decision-making, and self-execution, are absent in the offline programming mode of fixed non-standard automated production lines. In the future, artificial intelligence is expected to completely replace traditional production lines. To respond to customer and market demands, Haosen is also actively expanding into new business areas.

Haosen has now registered an embodied intelligent robot company in Shenzhen, established innovation centers for embodied intelligent robots at its dual bases in Dalian and Changzhou, built experimental verification laboratories and training areas, and constructed highly flexible intelligent production lines to address industry challenges such as low capacity utilization and rapid product iteration.

Over the next 5 to 10 years, Haosen’s strategic goal is to develop independent intelligent workstations centered on embodied intelligent devices, replacing traditional assembly-line mass production methods. This will enable composite robots, legged or fixed-base embodied intelligent robots, humanoid robots, and embodied intelligent equipment and tools to operate collaboratively on production lines. Currently, our top priority is to develop specialized robots with embodied intelligence, continuing our collaboration with strategic partners such as AgiBot and the Zhejiang Humanoid Innovation Center to address Haosen’s gaps in large model training, motion control, and perception & decision-making technologies.

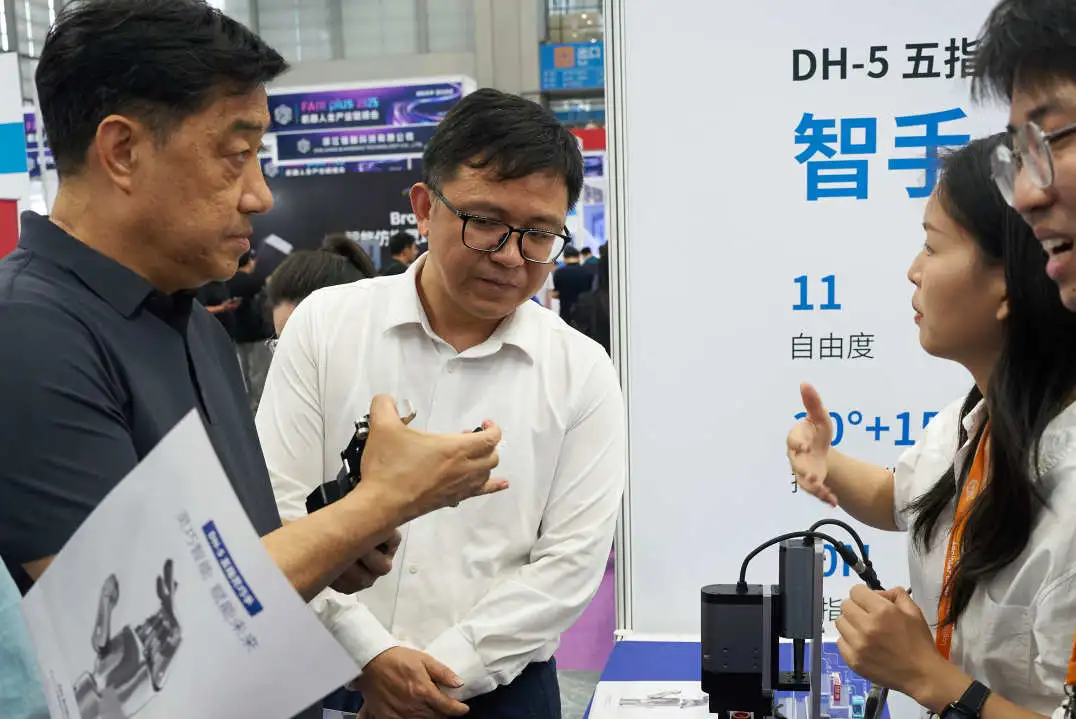

Moving forward, based on our embodied product portfolio and development plan, Haosen will deepen collaborations with key component manufacturers, such as collaborative robotic arms, AGVs, dexterous hands, and vision systems, as well as general-purpose robot companies like AgiBot and Unitree to meet the needs of Haosen’s integrated production line design and planning solutions.”

Haosen also looks forward to collaborating with more industry peers to achieve win-win results hand in hand on the new journey of “Intelligence Igniting the Future, Chain Driving the Globe,” contributing Chinese wisdom and solutions to the transformation and upgrading of global intelligent manufacturing.